If you weren’t able to attend drupa 2016, you weren’t alone. Of the 260,000 visitors who converged upon Messe Düsseldorf from May 31 to June 10, only a relative handful came from the U.S. The high cost of travel and the difficulty of breaking away from busy production schedules ruled out attending for many American printers who would otherwise have liked to go.

If you weren’t able to attend drupa 2016, you weren’t alone. Of the 260,000 visitors who converged upon Messe Düsseldorf from May 31 to June 10, only a relative handful came from the U.S. The high cost of travel and the difficulty of breaking away from busy production schedules ruled out attending for many American printers who would otherwise have liked to go.

If you’re based in the New York City metro area, however, there’s a next best thing to having been there: the Post drupa Report that Printing Industries Alliance will host on Thursday, August 18, 2016, at Club 101 (101 Park Avenue at 40th Street) in Manhattan.

From 9 a.m. to 6 p.m., some of the leading exhibitors from drupa 2016 will re-create the excitement of the event with panels and presentations before an audience of end users including printers, mailers, and other graphic arts service providers.

Printing Industries Alliance believes that end user decision makers need up-to-date information to navigate the graphic arts marketplace. Because most U.S. printers did not go to Germany, they must rely on after-the-fact information that can be daunting, confusing, and sometimes even contradictory. The Post drupa Report on August 18 is designed to give end users the information they need, firsthand and with clarity and balance. This will be delivered by expert panels on subjects such as:

• Who’s On First? Offset vs. Digital vs. Inkjet vs. Nanography

• The Rapid Rise and Importance of Labels and Packaging

• The Growing Importance of Color Management

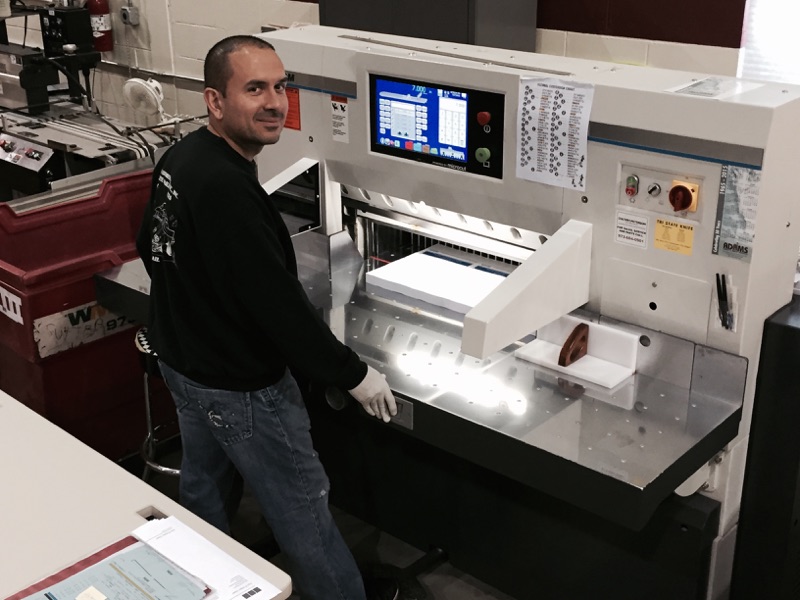

• Postpress Rules

• Wide Format Breaks into the Big Time

• Firsthand Observations from drupa Attendees

The all-day program will intersperse presentations and panels and will feature a lunch with a speaker to be announced. Also included are a vendor / end user networking session and an open bar at 5 p.m.

The cost is $99 for PIA members and $139 for non-members. Each additional member from the same company will cost $79 for members and $109 for non-members. To register for the event, contact Kim Tuzzo at 716-691-3211 or ktuzzo@pialliance.org. Register online here or download, complete, and return the registration form.

Printing Industries Alliance President Tim Freeman commented, “The Printing Industries Alliance wants to make sure that everyone in our industry has access to all the information they need to do business in the most efficient way. Events like this Post drupa Report do this and more. They provide a meaningful dialog between all parties and a great opportunity to learn from one another.”

Select vendor sponsorships are still available. For information on sponsoring the event, contact Marty Maloney at 203-912-0804 or mmaloney@pialliance.org. Vendor sponsors receive a 12-minute presentation slot, a seat on a panel, and a 5′ table to display literature at the end-of-day networking session.