On July 17, George Heinrich, “The Postal Professor, guided about 40 MFSANY and PIA members through the basics of dealing with the U.S. Postal Service.

On July 17, George Heinrich, “The Postal Professor, guided about 40 MFSANY and PIA members through the basics of dealing with the U.S. Postal Service.

If you are already a mailer, the following statement about dealing with the U.S. Postal Service (USPS) won’t shock you. If you are thinking about adding mailing to the list of services that your printing company offers, consider it very carefully.

“I’ve been in this business for almost 40 years,” said “The Postal Professor,” a.k.a. George Heinrich, “and for most of that time, it’s been an adversarial relationship.” But, he emphasized that his experience isn’t unique. Every company that prepares printed matter for entry into the mailstream has an “uncontrollable business partner” in the Postal Service, Heinrich said.

Managing the USPS relationship to the extent that it can be managed was the theme of “Postal Boot Camp,” a seminar that Heinrich conducted on July 17 for a group of about 40 people representing lettershops or printing firms that mail for their customers. The all-day program, held at the 101 Club in Manhattan, was a joint presentation of two metro area trade groups, the Mailing & Fulfillment Service Association, New York Chapter (MFSANY) and Printing Industries Alliance (PIA).

Heinrich’s purpose wasn’t to lambast the USPS, an organization he knows through and through from decades of work as the owner of direct mail businesses and as a high-level mailing manager for graphic communication firms. Today, as The Postal Professor, he lectures and consults to help clients profit from more thorough compliance with USPS regulations—a body of rules that confounds even postal personnel with its labyrinthine complexity.

As he put it to his Postal Boot Camp recruits, “What you’re going to learn today are a whole lot of simple little things that wound up costing a lot of money” needlessly because someone put a fold in the wrong place, failed to double-check the positioning of an address, or committed some other processing error that the USPS could and did penalize by charging a higher rate or even declaring the job undeliverable.

He also noted the arbitrariness with which the rules can be applied. Much of what happens to mailings still depends, he said, on the competence and the attitudes of individual USPS representatives—some of whom will know and enforce the fine points, others of whom will not.

The differences in degrees of acquaintance with USPS rules on the part of USPS employees can be “amazing,” according to The Postal Professor.

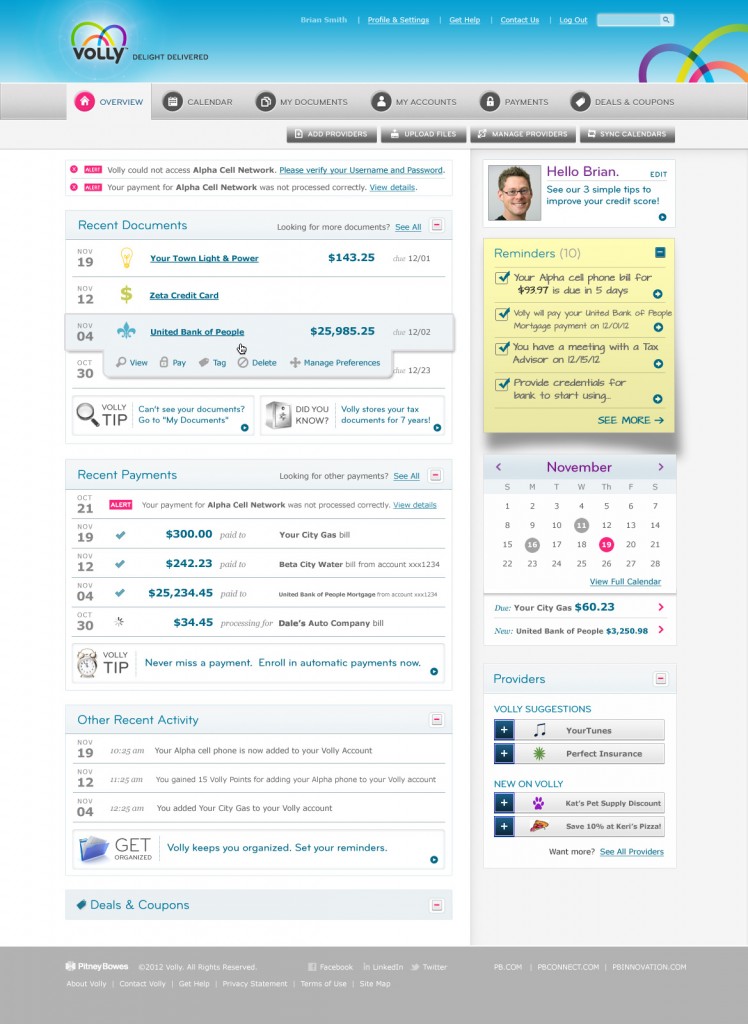

Delivering his overview with the help of detailed visuals and affable humor, Heinrich covered postal acronyms, classes of mail, sizes and dimensions, barcodes and automation, addressing, presorting, and data management. He also updated the MFSANY and PIA members on significant changes coming their way, such as the mandate to adopt Intelligent Mail Barcoding (IMB) for some classes of mail in January 2013.

The Postal Service, he reminded them, is by nature “a behemoth—something abnormally large and powerful” with rules that can neither be sidestepped nor bent. However, it is not the behemoth that it used to be.

Last year, despite the fact that the number of addresses in the U.S. increased by more than 600,000, the USPS processed 122 million fewer pieces of mail per day than it did in 2008. Operating at a multibillion-dollar net loss, and likely to default on prepayment of future healthcare and retirement benefits, the Postal Service will have to resort to delivery cuts, staffing reductions, consolidation of facilities, and other painful measures to regain stability.

“So, what’s troubling the USPS?” asked Heinrich. He didn’t completely answer the question, but he reminded his audience that whatever lies at the heart of the Postal Service’s problems affects the entire printing and mailing industry as well.

USPS revenues come almost exclusively from the sale of postage, and the mail it handles falls into two broad categories of acceptance: retail or “raw” mail for which the Postal Service does all of the sorting and processing; and discounted mail, in which some of that work is done by the originators. Most of Heinrich’s presentation consisted of practical tips aimed at helping mailers maximize the discounts they can earn by presorting, accurately addressing, barcoding, and otherwise streamlining the mail flow before the Postal Service begins handling individual pieces.

The USPS cannot offer volume-based discounts for most classes of mail. Instead, it rewards mailers for worksharing that makes it easier for the Postal Service to get the mail to its final destination. Discounts also apply to mailing pieces that are sized for compatibility with the Postal Service’s automated sorting equipment.

Worksharing can be a profit center for printers and mailers whose customers count on them to have this kind of expertise—“and I hope that you’re charging for that expertise,” Heinrich said.

The repository of all postal rules and regulations is the Domestic Mail Manual, an 1,862-page document so exquisitely detailed, Heinrich said, that it even addresses the mailability of “small, harmless, cold-blooded animals” such as baby alligators (see section 601.9.3.3). Much of what is in the DMM “is subject to interpretation,” according to Heinrich, who added that in passages where the words “must,” “should,” “may,” and “may not” appear, meanings need to be parsed with extra care.

Heinrich devoted considerable time to the correct design of mailing pieces and the necessity of formatting and printing them exactly the way the USPS expects to receive them. He distributed templates specifying dimensions, aspect ratios, thicknesses, address placements, and other parameters that mailing pieces must satisfy in order to be deemed “machinable” (capable of being handled by the Postal Service’s automated systems) at discounted rates.

From left: Rocco Pozzulo, Lazarus Marketing Inc. (Oceanside, NY), MFSANY board; George Heinrich; Martin Rego, Century Direct (Long Island City, NY), MFSANY board; James W. Prendergast, executive director, MFSANY.

From left: Rocco Pozzulo, Lazarus Marketing Inc. (Oceanside, NY), MFSANY board; George Heinrich; Martin Rego, Century Direct (Long Island City, NY), MFSANY board; James W. Prendergast, executive director, MFSANY.

Heinrich also presented a gallery of “The Good, The Bad, and The Ugly”: design errors that caused the pieces to incur higher-than-anticipated mailing costs.

For example, a self-mailer with an improper aspect ratio had to be manually handled at an upcharge of nearly $50,000. Similarly, a mailpiece with an incorrectly placed vertical fold was kicked up from the automation rate to the higher per-piece charge of a non-machinable letter. Another with the wrong ancillary endorsement line—“return service requested” instead of “change service requested”—cost its mailer three times more per piece than it should have.

What these flubs point to, said Heinrich, is the urgency of educating direct-mail customers—and their designers in particular—about the rewards and the penalties attached to preparing mail for postal entry.

Nothing is more urgent for mailers to master than barcoding, the imprinting and databasing technique that makes automated mail handling possible. Barcodes now appear on most letters and flats (mailpieces with at least one dimension larger than lettersize). Heinrich reminded the group that the USPS offers its best worksharing discounts to mailers who apply barcodes before the pieces enter the mailstream.

On January 28, 2013, use of the Intelligent Mail Barcode (IMB) will become mandatory for mailers wishing to qualify for automation discounts. The IMB, which can encrypt 1,000 times more information than the barcode format it replaces, facilitates sortation all the way to the final point of delivery. It also makes individual pieces trackable, and it contains an automated address change feature as well.

A show of hands indicated that most in the room were familiar with IMB and were either using it or preparing to adopt it. They were less confident about Full Service IMB, a phase of the program that the Postal Service probably will require mailers to join in 2014. Taking part in Full Service IMB secures automation discounts, but it also imposes what Heinrich described as burdensome compliance requirements: electronic filing, investment in software, and testing by the USPS.

Full Service IMB as it is presently structured offers “zero advantage to the mailer,” he said. “The pain level involved in participating in Full Service IMB is very high.”

Heinrich adjourned the Postal Boot Camp with resources and recommendations, one of which was to stay on friendly terms with the personnel at one’s local BMEU (Business Mail Entry Unit). A USPS listserv that can be joined at dmmadvisory@usps.com (“subscribe” in the subject line) sends regular updates on regulatory changes.

The Postal Professor can be reached via his favorite medium at Postal 911, P.O. Box 3096, Parker, CO 80134-1428. His “Postal Hotline” number is 303-325-3048. (MFSA members get 30 minutes of free consultation.) E-mail him at help@postal911.com.